AEOLOS is the first mover into the UAE Center for Sustainable Ship Building in Ras Al Khaimah

- hg2775

- Mar 3, 2024

- 2 min read

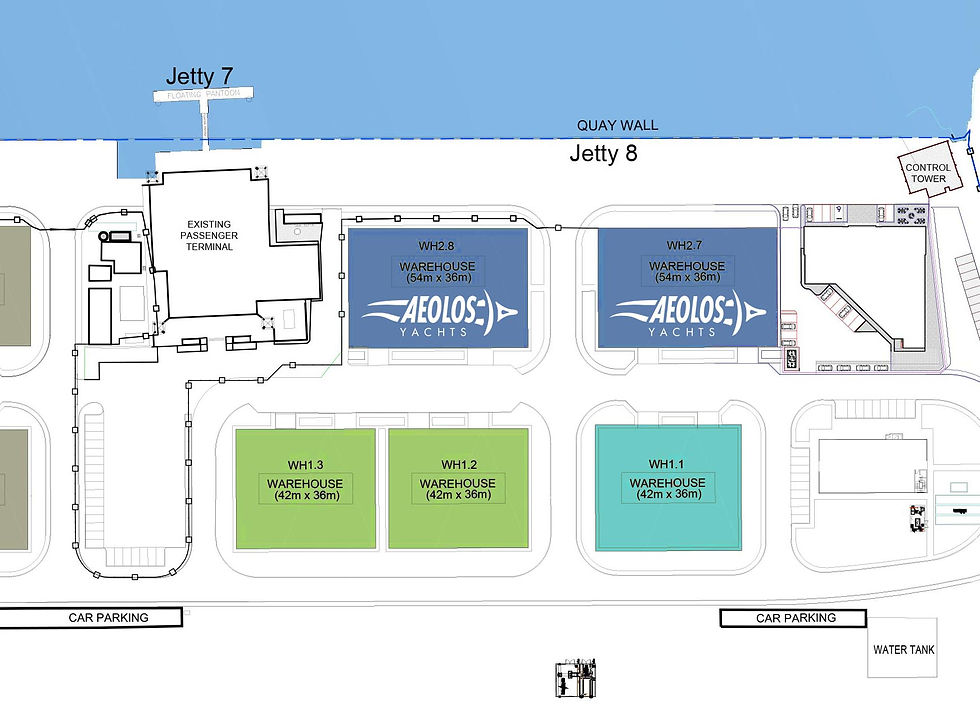

3.3.2024. A quantum leap for AEOLOS: we are moving to new facilities, occupying 4000 square metres of covered sheds right on the waterfront in the Kohr Port Ras Al Khaimah Freezone.

The office and workshop is 3 days closed, from 4.4.-6.4., opens in Ras Al Khaimah again at Thursday. 7.4.2024

This new facility enables us to offer high quality repair and refit services for motor and sailing yachts launched over the quayside. We also offer a pick-up service with an AEOLOS crane truck for boats up to 9 metres and 6 tonnes in weight.

Easy launching at the quay side in front of the factory.

2 fully equipped facilities and room to grow.

Easy access from the sea and from the land.

Aeolos is part of the Center for Sustainable Ship Building in Ras Al Khaimah. Further 13 companies have signed a letter of intent for moving into the new cluster.

Our scope of work:

New build of yachts

New build of carbon spars (masts, booms, etc.)

refits

Keel/Rudder alignment

Structural repairs at hull, keel and rudder

Gelcoat repairs/painting

Polishing and waxing

Fittings production in stainless steel, titanium, aluminium, carbon

Rigging

Sail repairs

Upholstery

Trailer repairs: brakes, new wheels, welding, light check, RTA-approval

New trailers (with axis/coupler/brakes made in Germany)

Composite work shop

• CNC mould milling machines • 3D printing module (coming soon)

• Curing oven for prepreg production process

• Paint booth with AC cooled air supply, high quality SATA and Mirca equipment

• several clean rooms

Metal work shop

• milling machine for Aluminium moulds in Aerospace quality

• 2 CNC Milling Centers, Aerospace standard

• Lathe ø800 x L 2000mm and Lathe ø1800 x 1600mm

• Metal Saw, band saw, horizontal boring and balancing machines

• Polishing machines

Composite Carpentry

• 3-axis CNC cutting/routing/drilling

• Sliding table saw

• 2 Edge banding machines

• Jointer

• Thickness planer

• Veneer press and Veneer joining machine

• Table router

• Wide belt sanding machine

• Furniture paint booth

Quality Management

• Hexagon CMM for high precision complex 3D geometries measurement (1,3 μm)

• Complete set of measuring tools, granite benches, height gauges.

Rigging

• WIRETEKNIK Swagging Machine 2,5 -12mm wire terminals

• High end splicing equipment with winch

• Wig & Mig welding for Steel, Stainless steel, Aluminium and Titanium

• Chain blocks and A-Frames

Upholstery, Textile printing, Templates- & Signmaking

• 160cm LFP Printer/160cm Plotter

• 160cm LFP Textile Printer with Calander heating for textile paint fixing

• sewing machines for upholstery and sail repairs

Facilities

• 2 x 2000 sqm insulated factories with 4 sliding doors

• 6 clean rooms with stable temperature/airconditioning system

• 4 Offices, Meeting Room, Pantry

• Reception/Accounting/HR in the Harbour Office

Service Fleet

• Mercedes Crane Truck, 8m loading platform with 10t 20m crane

• 2 street trailers for boat transport

• stapler

Commentaires